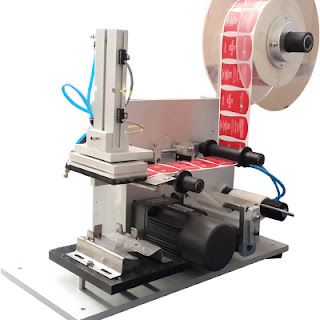

Leveraging on our present day

infrastructure facilities, we are able to provide a huge range of sticker

labeling device. To be able to ensure the flawlessness, these labeling machines

are strictly examined on one-of-a-kind parameters.

|

| Sticker Labeling Machine |

The system meets demands of

excessive speed running. It consists of all electric specifications like

pressing tool Motor, Conveyor Motor, and sticky label Roll Stepper Motor. This Labeling Machine is able to give an output of various label length. This low weight

system is extensively appreciated the impeccable overall performance, advanced

electricity, longer provider life. Using on unfathomable volumes of industrial

knowledge, we're supplying a great single side sticky label Labeling device.

Consistent with set enterprise standards, the offered device have precisely

engineered the usage of high-quality confident components and high-end

technology with the aid of our skilled professionals. The product is absolutely

computerized and has Slat conveyor, Optical label scanner, Label dispenser

unit, develop a controller, Label pressing assembly and so forth.